Built-in Capabilities Make Infor Arguably the Best ERP for Manufacturing

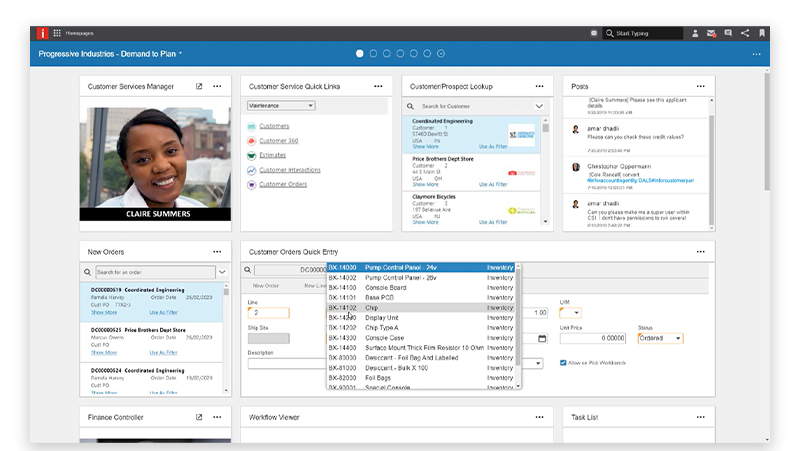

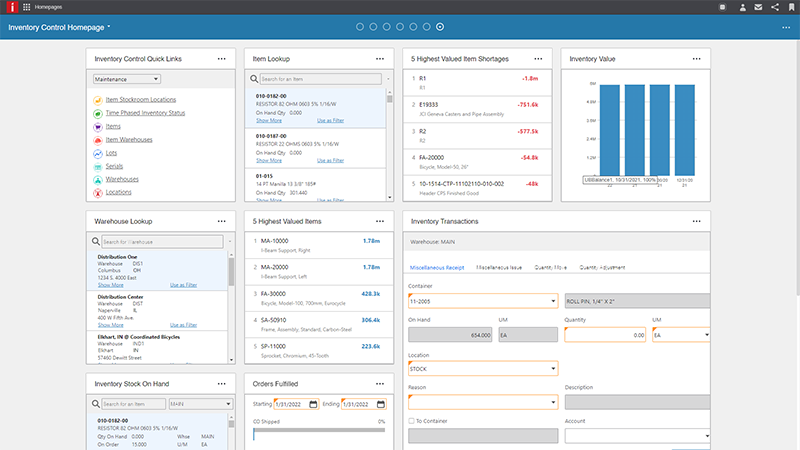

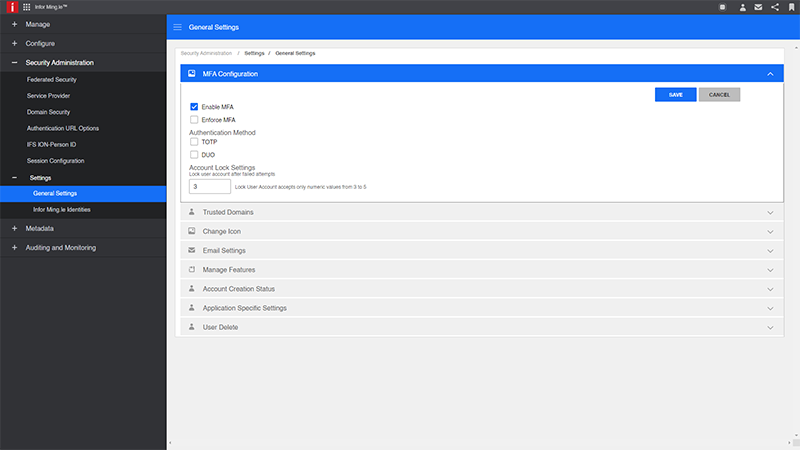

Infor is a leading enterprise resource planning (ERP) solution for manufacturers that require industry-specific, flexible, and scalable capabilities. For more than 30 years, Infor’s SyteLine manufacturing ERP software has helped 6,000+ organizations achieve greater outcomes and accelerate growth using automation and data-driven decisions━all from one, integrated platform. Infor SyteLine can be deployed in the cloud or on premise, and can operate 100% cloud based for those that prefer it.

Infor ERP Benefits Manufacturers Can Expect

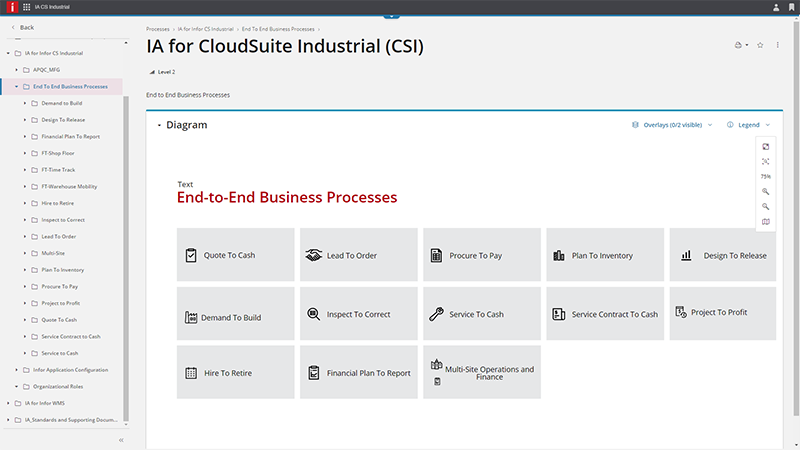

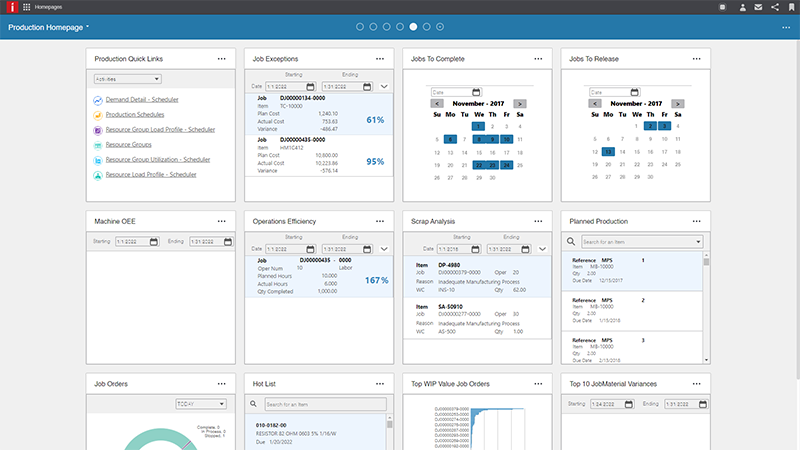

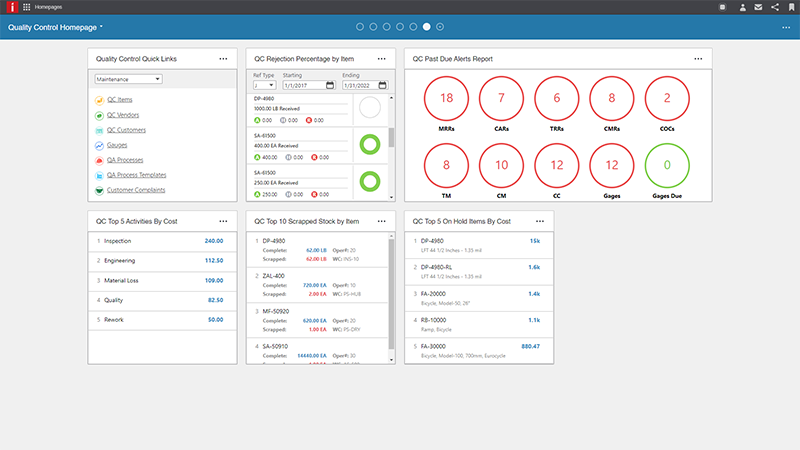

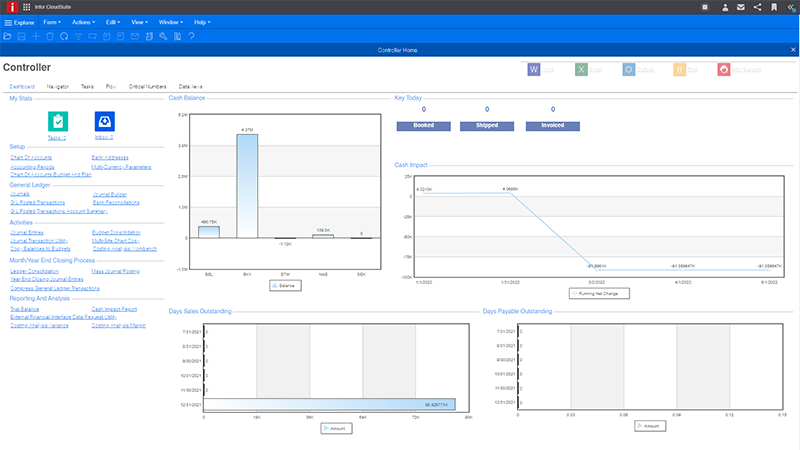

Infor ERP Modules that Manufacturers Love

Of the Top 3 ERP systems globally, Infor is the preferred ERP solution for small- to mid-size manufacturers–and for good reason. Its industry-specific capabilities support complex manufacturing needs right out of the box with less customization and faster deployments.

Manufacturing ERP Case Studies

Mastercool Chose Copley Consulting Group and Infor ERP to Transform Their Business Processes

Mastercool is a family-owned company that has supplied professional quality air conditioning service tools and equipment for over 35 years. As one of the fastest-growing companies in this market, their never-ending focus is on innovation and new technology. Mastercool products are distributed in over 76 countries.

Manufacturer Brought Infor ERP to Ireland Operations with Help from Copley Consulting Group

New York-based G.W. Lisk is a global leader in providing custom-engineered solutions to the aerospace, defense, on/off highway, and oil and gas industries. They are recognized as an innovator in technology and manufacturing.

ERP Implementation for Manufacturers

Copley Consulting Group has been an Infor Gold Channel Partner for nearly 30 years. We offer the expertise and project management resources to make your Infor ERP implementation seamless. In fact, we offer four implementation approaches to accommodate manufacturers small to large. The right approach is dependent on your organization’s goals and needs.